We establish a detailed understanding of site conditions to determine the best pump station size, flow rate, head pressure, storage requirements, odour control considerations and layout solutions.

Aquatec’s concrete and fibreglass pump stations form an essential part of water and wastewater infrastructure in our communities.

Aquatec is regularly consulted by regulatory and industry bodies, water authorities and councils across Australasia to provide pumping stations for complex infrastructure requirements.

Aquatec pump stations along with our end-to-end processes have set new standards in environmental risk management, safety and serviceability.

Our custom approach to control systems delivers a consistently high level of operational integrity.

Select a product

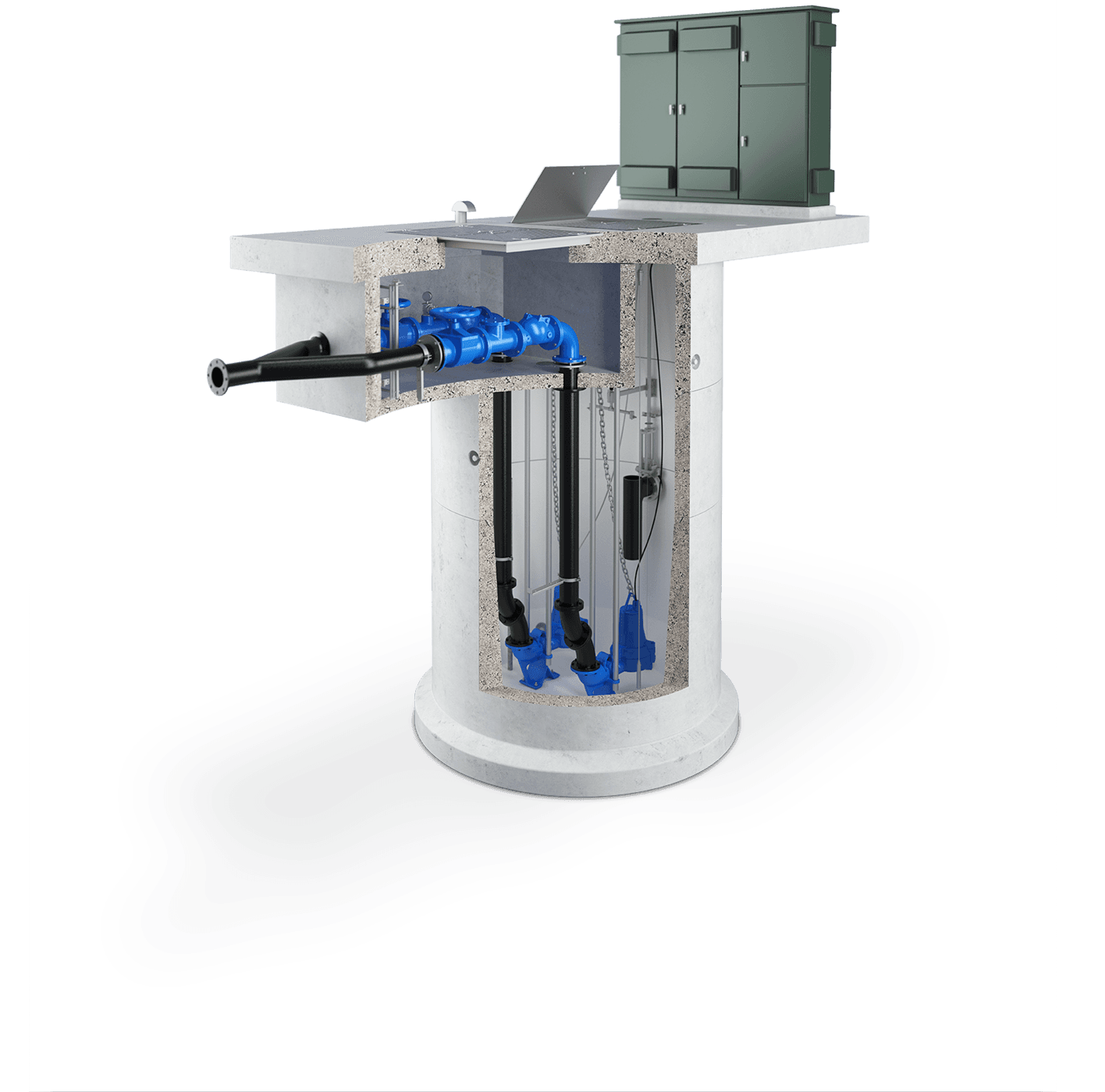

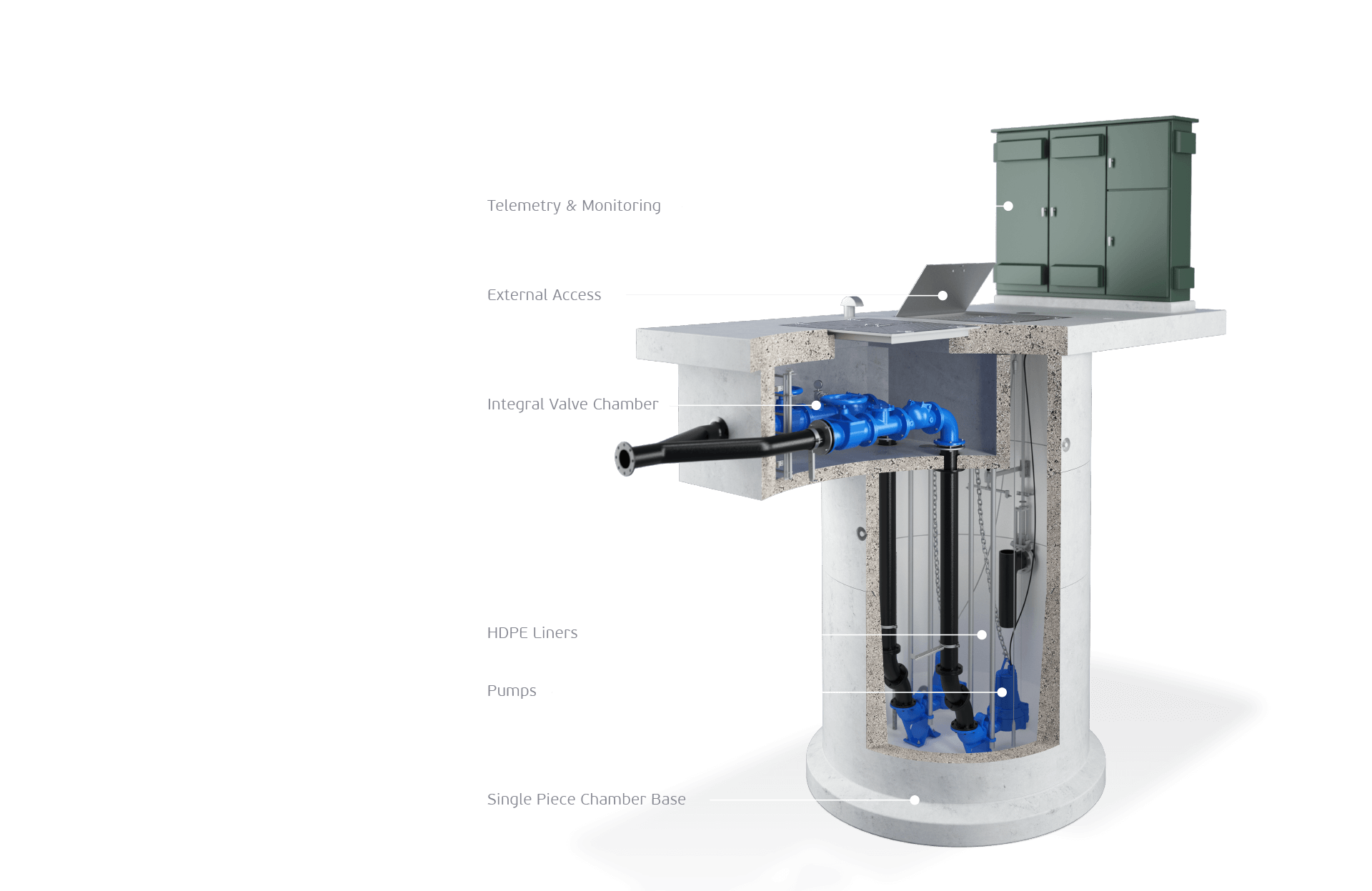

Concrete Pump Stations

Structurally engineered to deliver on individual project specifications, operational requirements and site conditions.

SelectConcrete Pump Stations

Aquatec concrete pump stations are structurally engineered to deliver on individual project specifications, operational requirements and site conditions.

Select

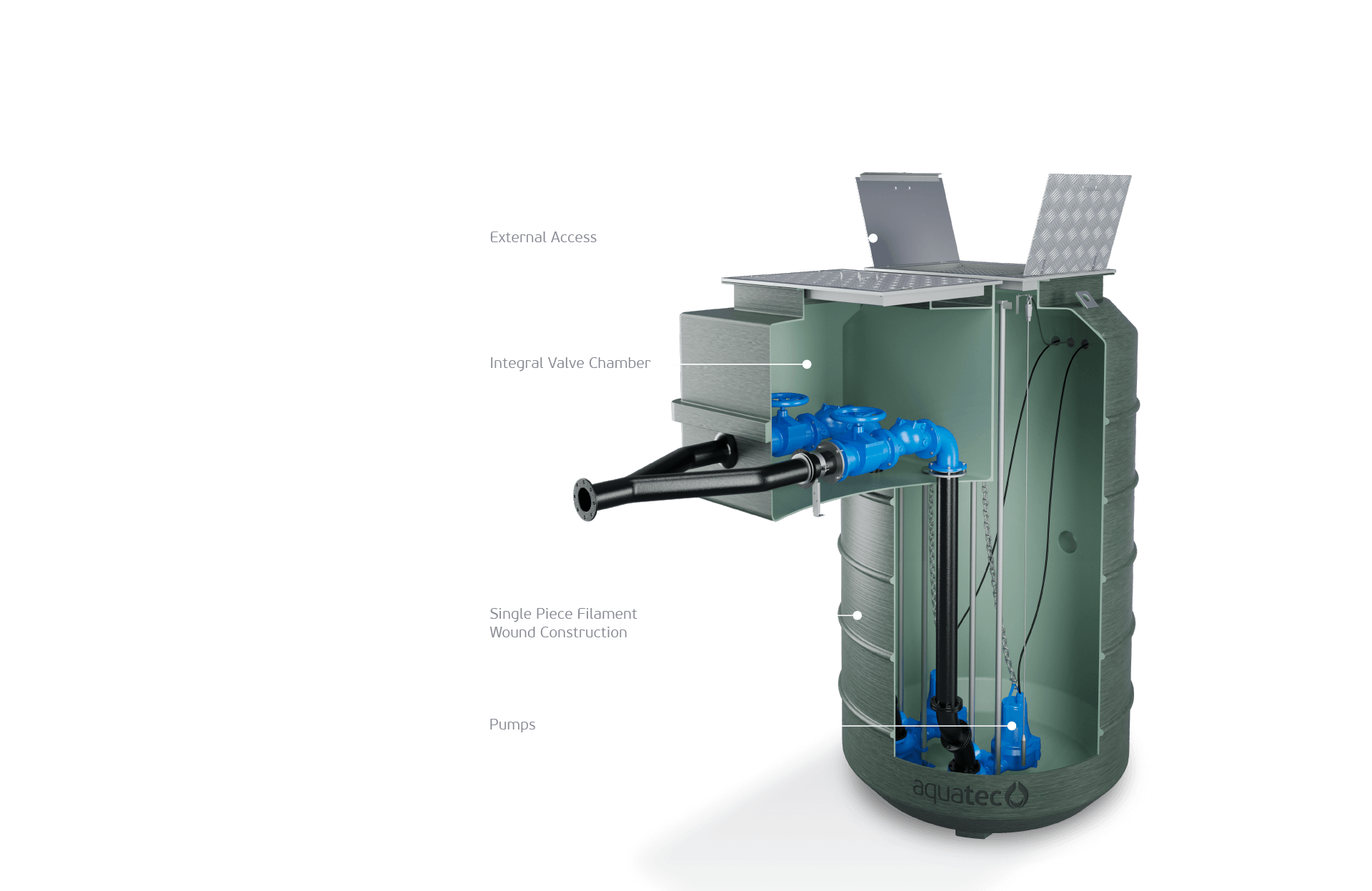

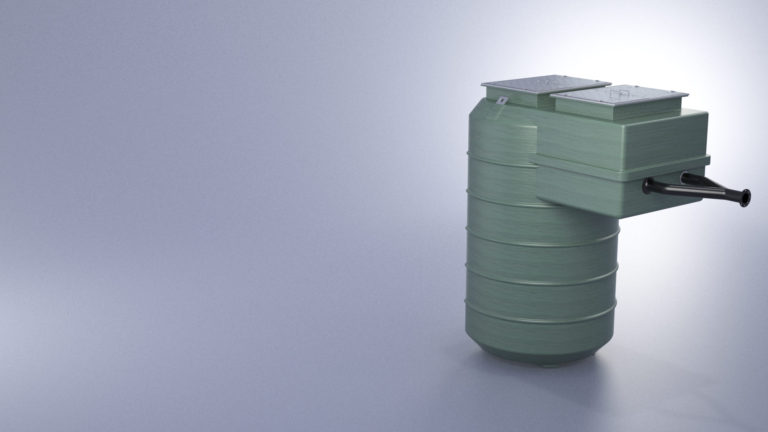

Fibreglass Pump Stations

Manufactured as a one-piece vessel to exact project specifications, allowing for a seamless installation process.

SelectFibreglass Pump Stations

Aquatec’s fibreglass pump stations are manufactured as a one-piece vessel to exact project specifications, allowing for a seamless installation process.

SelectConcrete Pump Stations Tailored For Every Project

Engineered with S50 (50 MPa) concrete to exceed Australian standards, structural integrity continues to be central to our precast pump station designs.

We tailor each concrete pump station to perfectly suit the individual specifications of each project, drawing on our years of experience to make this a seamless process for you. Product integrity is vital to us, and has been at the core of our operations for the last 30 years, setting a new standard in engineering quality within the industry.

We reach this through our focus on perfection from design through to commissioning. Aquatec is regularly consulted by regulatory and industry bodies, water authorities and councils across Australiasia to provide pumping stations for complex infrastructure requirements.

Specifications

| Internal Diameter | 1800mm |

|---|---|

| Integral Valve | 1200 x 1200mm |

| Increment Size | 315-1000mm |

| Max Depth (m) | 15m* |

| Capacity Per Extra Metre (Litre) | 2,500L |

*Deeper available on request

| Internal Diameter | 2250mm |

|---|---|

| Integral Valve | 1500 x 1500mm |

| Increment Size | 500-2500mm |

| Max Depth (m) | 15m* |

| Capacity Per Extra Metre (Litre) | 3,950L |

*Deeper available on request

| Internal Diameter | 3200mm |

|---|---|

| Integral Valve | 2200 x 1800mm |

| Increment Size | 500-2500mm |

| Max Depth (m) | 15m* |

| Capacity Per Extra Metre (Litre) | 8,000L |

*Deeper available on request

| Internal Diameter | 3600mm |

|---|---|

| Integral Valve | N/A |

| Increment Size | 750-2500mm |

| Max Depth (m) | 15m* |

| Capacity Per Extra Metre (Litre) | 10,000L |

*Deeper available on request

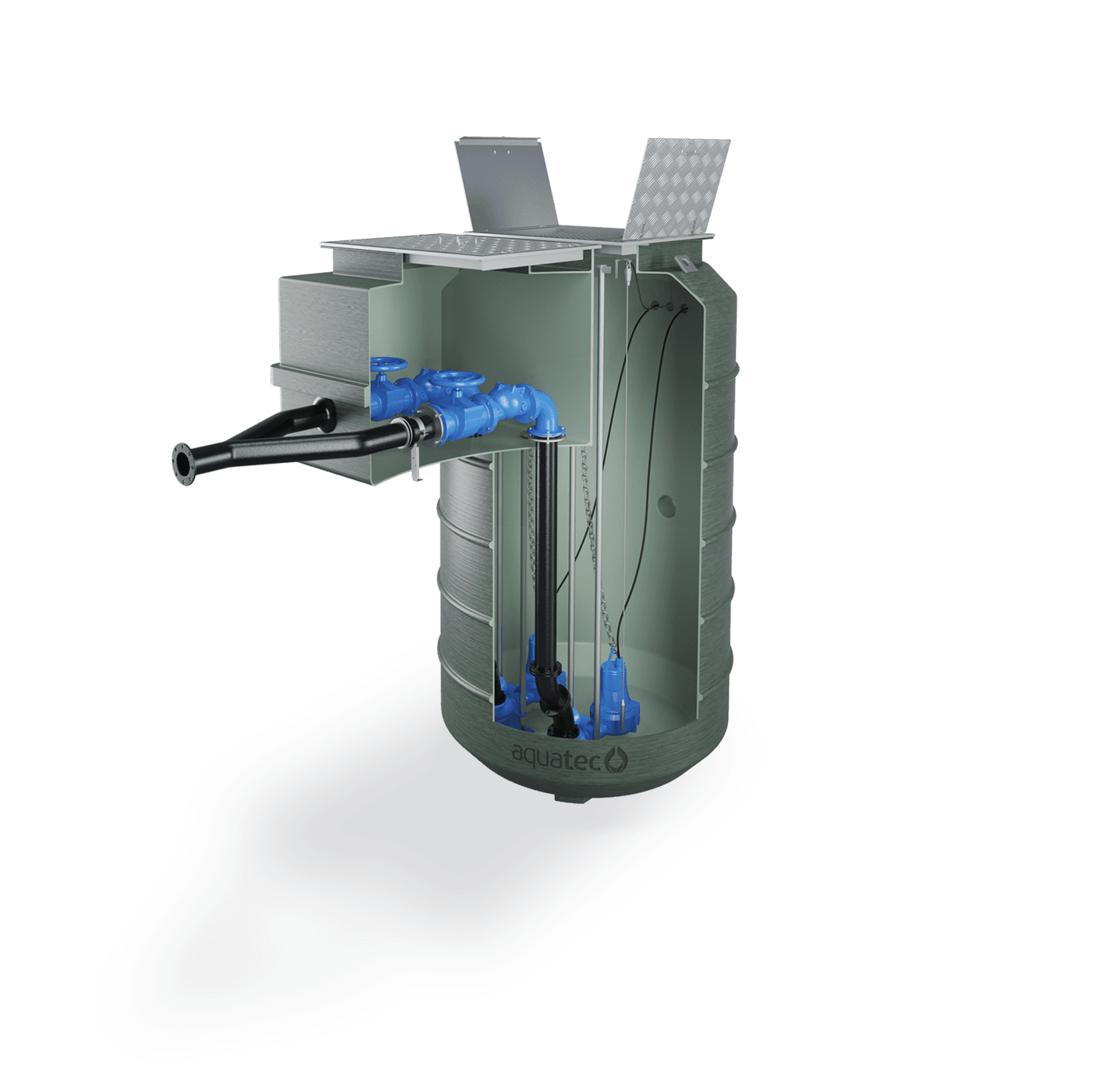

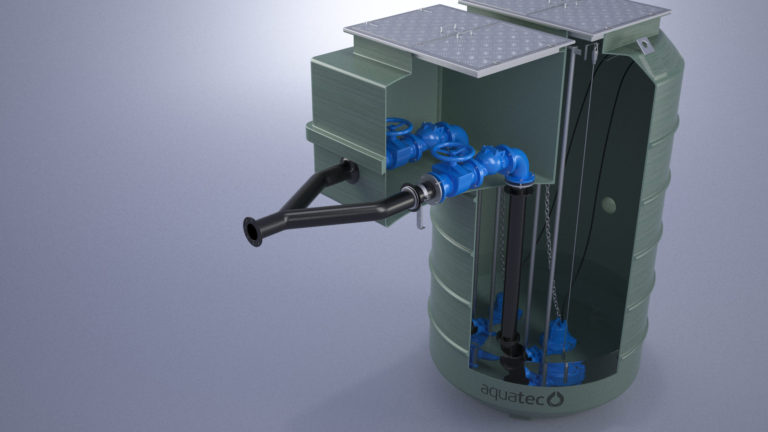

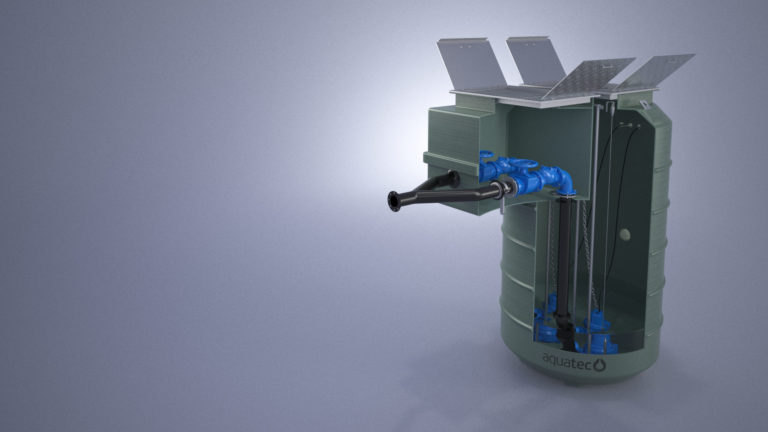

Fibreglass Pump Stations Manufactured To Precise Specifications

Aquatec fibreglass pump stations are manufactured as a one-piece vessel to individual project requirements, and delivered on site as a complete unit for easy installation.

Each fibreglass pump station is engineered to withstand internal and external loadings across all ground conditions. For more than 30 years, our commitment to product innovation has remained central to the development of our fibreglass pump stations.

We recognise that by taking a holistic approach to design and delivery, we can ensure a seamless experience regardless of a project’s specifications and site conditions. Aquatec pump stations along with our end-to-end processes have set new standards in environmental risk management, safety and serviceability.

Specifications

| Diameter (mm) | 1250mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 1,200-24,000L |

*Deeper available on request

| Diameter (mm) | 1500mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 1,700-34,000L |

*Deeper available on request

| Diameter (mm) | 1800mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 2,500-50,000L |

*Deeper available on request

| Diameter (mm) | 2000mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 3,100-62,000L |

*Deeper available on request

| Diameter (mm) | 2500mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 4,900-98,000L |

*Deeper available on request

| Diameter (mm) | 3000mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 7,000-140,000L |

*Deeper available on request

| Diameter (mm) | 3500mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 9,600-192,000L |

*Deeper available on request

| Diameter (mm) | 4000mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 12,500-250,000L |

*Deeper available on request

| Diameter (mm) | 4500mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 15,900-320,000L |

*Deeper available on request

| Diameter (mm) | 5000mm |

|---|---|

| Depth (Metres) | 1-20m* |

| Volume (Litres) | 19,600-392,000L |

*Deeper available on request

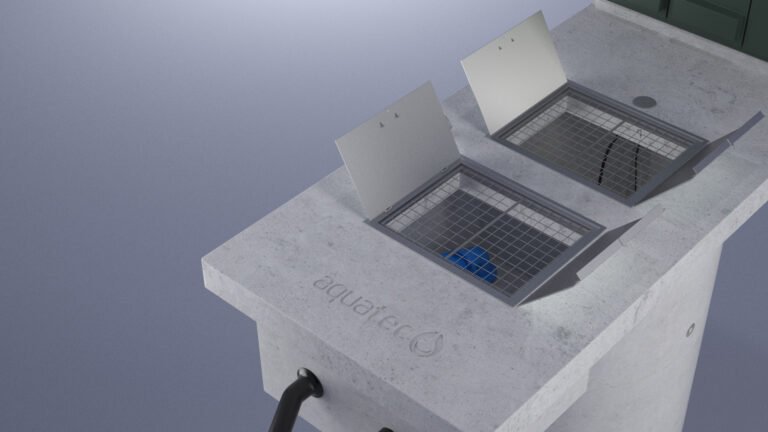

One-piece cover slab

This innovative slab houses the lids, switch board cubicle, vent stack and reduced pressure zone assembly, eliminating additional onsite concrete works.

Meeting all WHS standards

Our pump station access meets every water authority and council requirement, designed along with our fall arrest barriers.

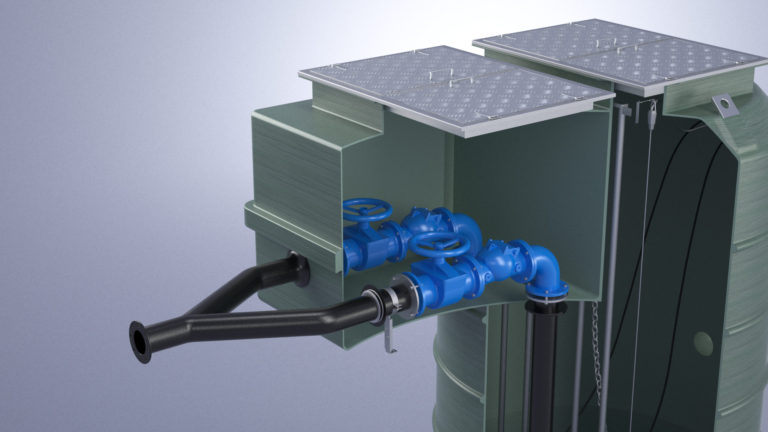

Valve chamber options

Our integral valve chambers prevent differential ground settlement, while our external valve chambers suit large pipeworks.

Protection against corrosive gases

Our internal chamber coatings and H2S-resistant high-density polyethylene (HDPE) liners lock into all concrete surfaces.

Mould form construction

Delivers an impervious finish with a minimum concrete strength of 50 MPa for consistent cover.

One-piece cover slab

This innovative slab houses the lids, switch board cubicle, vent stack and reduced pressure zone assembly, eliminating additional onsite concrete works.

Meeting all WHS standards

Our pump station access meets every water authority and council requirement, designed along with our fall arrest barriers.

Valve chamber options

Our integral valve chambers prevent differential ground settlement, while our external valve chambers suit large pipeworks.

Protection against corrosive gases

Our internal chamber coatings and H2S-resistant high-density polyethylene (HDPE) liners lock into all concrete surfaces.

Mould form construction

Delivers an impervious finish with a minimum concrete strength of 50 MPa for consistent cover.

Fully compliant

Built to Australian and British standards, certified by a registered composite engineer.

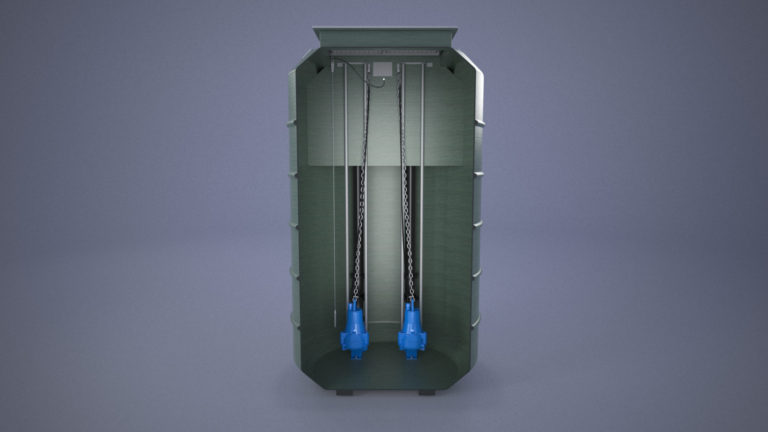

Designed to last

The unique chamber is mould formed as one piece for strength, durability and functionality.

Integral valve chambers

These eliminate the line-up of separate valve chambers and prevent differential ground settlement.

Benchmark quality

The filament is wound through a computerised winder and manufactured with the highest-grade resins.

External access

The pump station is designed to provide maximum protection for maintenance personnel.

Fully compliant

Built to Australian and British standards, certified by a registered composite engineer.

Designed to last

The unique chamber is mould formed as one piece for strength, durability and functionality.

Integral valve chambers

These eliminate the line-up of separate valve chambers and prevent differential ground settlement.

Benchmark quality

The filament is wound through a computerised winder and manufactured with the highest-grade resins.

External access

The pump station is designed to provide maximum protection for maintenance personnel.

00 What we do for you

By taking a holistic approach to our water and wastewater solutions, we guarantee a perfect end-to-end solution with no hidden costs.

01 Design

Our design engineers work closely with you, analysing all aspects of the project, providing a complete set of drawings/hydraulic calculations for construction, and consulting with relevant water authorities.

02 Procurement

Our procurement schedule maps out all components of your asset, including any critical time components to ensure they align with your construction program.

03 Construction Program

A dedicated project manager establishes a construction program that works for you and ensures timelines and key milestones are met.

04 Pre-Start Meeting

Upon approval of design drawings, our site construction managers go through every step of the process with your team, from delivery of the structural components to commissioning and handover.

05 Craning & Excavation

Our detailed craning and excavation brief includes lifting methods, weights, the excavation size and backfill requirements to ensure the integrity of your asset.

06 Pre-Assembly

We pre-assemble all relevant mechanical components at our facility under controlled environments to ensure a smooth build on-site and seamless installation with quality assurance.

07 Civil Installation

Our installation training allows the civil contractor to be familiar with the process, backed by a civil installation guide with a step-by-step breakdown of what will be experienced on site and how we can help.

08 Mechanical Fitout

Under the direction of our lead field technician, our mechanical fitters install valves, pipework, pumps, guiderails, flow meters, landings and ladders, and connect pipework as per our offer.

09 Factory Acceptance Test

All equipment is thoroughly tested prior to delivery with a Factory Acceptance Test (FAT) which can be witnessed by relevant council or water authority personnel.

10 Electrical Fitout

Our electrical team connects the pump cables and level controls, places the electrical switchboard on the slab, and supervises all approvals of documentation with relevant power authorities.

11 On-Site Pre-Test

Prior to final commissioning, our technicians perform a thorough test of all mechanical components, pumps and flow rate measurements for accuracy, efficiency and compliance.

12 Final Commissioning

A complete re-run of the pre-tests includes all stakeholders and relevant water authorities, who connect their SCADA for final testing and approval. Our operation and maintenance training includes crosschecks for compliance and final sign-off.

13 Ongoing Support

We not only back the integrity of our system for the long term, our after-sales support provides peace of mind through refresher training and technical support.

Concrete & Fibreglass Pump Station FAQs

Aquatec works closely with clients to deliver expert knowledge across flows, friction loss, static lift, atmosphere, pipe sizing and air locks by taking into consideration development size, type of loadings and point of discharge.

Our modular designs reduce installation time and the need for excavation to be open. This saves costs, improves site safety and minimises impacts to the environment.

All Aquatec pump stations are manufactured in a controlled factory environment under strict ISO 9001 standards which guarantees whole of life and integrity of the asset.

Tailored individually to water authority and council requirements, our smart monitoring and telemetry systems integrate seamlessly with local SCADA and remote access platforms.

Aquatec is committed to providing full after sales service, support and long term warranty on all components and workmanship.

Aquatec have proven experience in the industry, and after reviewing the Aquatec design drawings we were confident it was going to be a standout product.

– CCA Winslow, Waterlea Sewer Pump Station Project

Fraser Coast Regional Council have been fortunate to have had the opportunity to work with Aquatec on a number of projects. The Council is confident that the pump station infrastructure solutions supplied by Aquatec will continue to perform at a high level through to the end of their nominal design lives and, in all likelihood, will continue to perform at a high level well past the nominal design life.

– Fraser Coast Regional Council, Aubinville Sewage Treatment Plant Project

Related Projects

Working together, working collaboratively.

Related Products

Aquatec offers a wide range of related products which work seamlessly together to enhance your project.

Storage Vessels

Custom designed for your project’s specifications, our fibreglass storage vessels are structurally engineered to handle critical inflows.

View MoreOdour Control

Aquatec partners with Biorem Technologies, a high-end manufacturer of biological odour control technologies for use in the water and wastewater industries.

View MorePressure Sewer

Aquatec pressure sewer systems are one of the most economical and environmentally friendly sewerage systems available.

View MoreWater & Wastewater Reuse

Our water and wastewater reuse systems reduce demand on potable water supplies for municipal, industrial and private projects.

View MoreGet in Touch

Have a question for us or wish to discuss a project? Send us some information using the contact form.

AU 1300 088 555 (within AU)NZ 0800 756 543 (within NZ)info@aquatecenviro.comHeadquarters

2 Provincial Crescent,

Shepparton, VIC 3630

Production Facility

56-60 Florence Street,

Shepparton, VIC 3630

Level 28, 2 Southbank Boulevard

Southbank, VIC 3006

Level 12, 50 Berry St

North Sydney, NSW 2060

9 Nello Place,

Wetherill Park, NSW

34 Kurzok Pl,

Richlands, QLD 4077

37-43 Brodie Road,

Lonsdale, SA 5160

Perth

Canning Vale, WA 6155

52 Orbell Street, Sydenham,

Christchurch 8023, New Zealand

Tenancy 5, 76 Porana Road,

Hillcrest, Auckland 0627, New Zealand