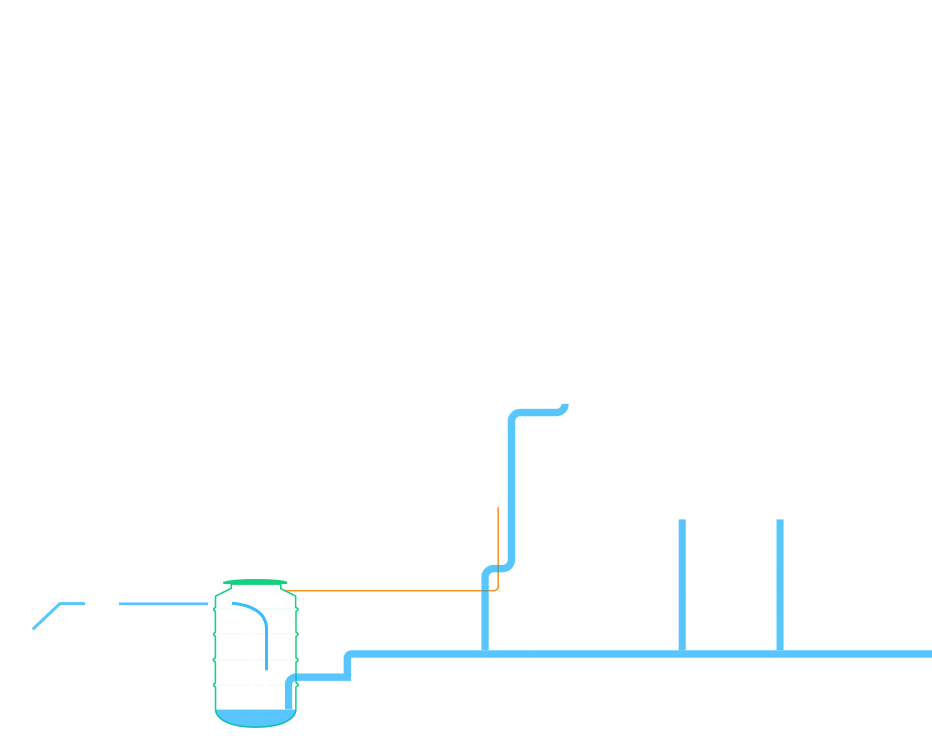

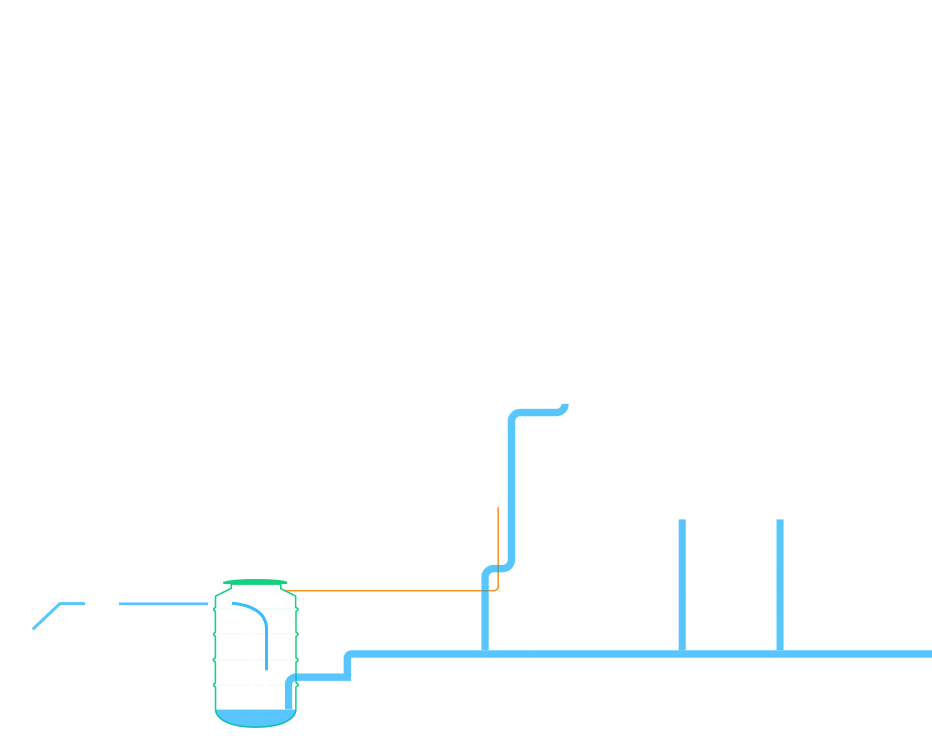

Fully automated, preprogrammed device that accurately controls flows within your reticulation network. By prioritising pump operation, it optimises your pressure sewer network and is fully upgradable to allow remote access.

“We are pleased to announce that Aquatec is now the official Australian Distributor of E/One products. We are thrilled we have been entrusted by E/One, a leading manufacturer and provider of products and services for the disposal of residential sanitary waste and Utility Systems for the protection and performance optimisation of electric utility assets, based in the USA, to be their partner in Australia.”

Harvey Seeley, Aquatec Global CEO

Our pressure sewer systems are customised to deliver up-front and long-term operational cost savings.

By taking a tailored approach to the design of pressure sewer systems, we ensure that all practical requirements and site conditions are met. The result is a carefully considered, economical and reliable solution.

Engineered with a domed base, designed to direct solids into the grinder of the pump. This eliminates the potential for solids build up in dead zones and associated odour issues.

The robust design translates into the industry’s highest levels of reliability and maintainability. E/One pumps are designed to run to failure with no preventative maintenance required.

Our reticulation valve kits are manufactured and tested to the highest standards using 316 stainless steel components and tested to a 16-bar operating pressure.

Residential pressure sewer solutions unlock development for complex terrains and topographies

Tailored residential pressure sewer solutions that are engineered to address the unique challenges of undulating terrain, rocky soil conditions, high groundwater tables, and flat landscapes. Designed to work seamlessly in conjunction with existing sewage collection systems, our approach enables communities to efficiently and reliably expand their service areas, even in the most demanding environments.

Various sizes are available to suit any installation environment. Sizes include 720 litres (most common), 850, 1000 and the 1300 litre duplex tank. Larger volumes are available in fibreglass and include duplex and quadplex arrangements. The tank is fitted with double O-ring seals, which make assemblies waterproof, and the novel joint geometry minimises the effects of crevice corrosion. The tank has a solid rib construction that will withstand the most challenging soil conditions.

Model 2010iW

- Dimensions: 800mm x 2100mm

- Capacity: 850 l

- Click to download the product specifications

Model 2011iW

- Dimensions: 1000mm x 2200mm

- Capacity: 1000 l

- Click to download the product specifications

Model 2013iW

- Dimensions: 1050mm x 1600mm

- Capacity: 800 l

- Click to download the product specifications

Model 2014iW

- Dimensions: 1100mm x 2200mm

- Capacity: 1320 l

- Click to download the product specifications

Residential Pressure Sewer Systems

What are the benefits of the E/One tanks?

Why do homeowners prefer the E/One tanks?

Residential pumps that guarantee the highest levels of reliability and maintainability

The E/One progressive cavity grinder pump serves as the core component of the pressure sewer system, offering a solution that can remove the need for expensive lift stations.

E/One pumps are designed to run to failure with no preventative maintenance required. The tank is accepted and used in high-head wastewater applications when solids are present. It is capable of achieving high head with a nearly consistent flow rate.

Grinder Pump Design Features

- 25-year design life with no preventative maintenance

- Dual O-Ring Seals provide simple assembly and rugged protection against water infiltration and corrosion

- Air Cooled Design eliminates the environmental risk of leaking oil and maintenance disposal

- Capacitive start motor generates high torque during start-up to prevent jamming. Permanent split capacitor designs create low torque and are susceptible to jamming

- Starting controls (capacitor, contactor, switches, etc.) are incorporated in the pump (vs. panel), which minimises heat and voltage drop

- E/One pump utilises the largest diameter grinder on the market (~130 mm vs 63 mm)

- Large diameter decreases inlet velocity & prevents binding & jamming

- Low speed and high-torque grinder is less likely to jam, bind or suffocate

- Does not require sharpness to function correctly and is a true macerator as opposed to a slicer

- E/One’s stainless steel discharge ball valve won’t corrode. No corrosion, no maintenance, no tools required.

Certifications

- NSF/ANSI 46 – 2007 Certified

- UL Certified

- CE Certified

- ISO 9001 – 2015 Certified

- AS/NZS 1546.1 Certified

Residential Pumps

What are the key elements to consider when selecting a pump?

What are the characteristics of the E/One residential pump?

Customised design approach meets the changing demands of commercial and industrial applications.

Aquatec’s Commercial Pressure Sewer Systems are among the most adaptable, economical, and environmentally friendly sewerage systems on the market today, offering a broad range of options tailored to your specific commercial site application. Fibreglass chambers can incorporate a Storage Vessel on a case-by-case basis for multiple commercial and industrial applications where greater storage is required.

Aquatec manufactures in accordance with the WSA07:2007 Pressure Sewer Code of Australia and holds JAS-ANZ third-party accreditation. Our Pressure Sewer Systems are manufactured in a controlled factory environment under strict ISO 9001:2015 quality standards. Proprietary chamber designs are pre-moulded to exact specifications, stringently tested and certified before delivery.

Our custom range of pressure sewer systems is regularly available for order across Australia and New Zealand. Please contact our team for more information about how we can help with your pressure sewer system solution.

Environmentally Friendly Solutions

Through ongoing research and development, we continue to develop the most economical, environmentally friendly and innovative systems on the market today.

Duplex Specifications

Duplex is a dual-pump system designed for use in multiple industrial or commercial applications. It is available as polyethylene or fibreglass construction, depending on the daily volume requirements.

PSS1100/ 1500/ 3000/ 5000/ 75000/10000/15000

- Litres (nominal): 1100/ 1500/ 3000/ 5000/ 7500/ 10000/ 15000

- Diameter: 1.0m/ 1.0m/ 1.5m/ 1.5m/ 1.85m/ 2.2m/ 2.5m

- Depth: 1.6m/ 2.2m/ 2.2m/ 3.0m/ 3.0m/ 3.0m/ 3.5m

- Depth to Inlet (max): 1.1m/ 1.7m/ 1.7m/ 2.4m/ 2.4m/ 2.4m/ 2.9m

Triplex Specifications

Triplex systems are constructed from fibreglass and are engineered for multiple commercial and industrial applications where larger tanks are required to handle higher daily flows.

PSS3000/ 5000/ 75000/10000/15000

- Litres (nominal): 3000/ 5000/ 7500/ 10000/ 15000

- Diameter: 1.5m/ 1.5m/ 1.85m/ 2.2m/ 2.5m

- Depth: 2.2m/ 3.0m/ 3.0m/ 3.0m/ 3.5m

- Depth to Inlet (max): 1.7m/ 2.4m/ 2.4m/ 2.4m/ 2.9m

Commercial and Industrial Pressure Sewer Systems

What is the difference between residential and commercial pressure sewer systems?

What are the applications of commercial and industrial pressure sewer systems?

Get in Touch

If you have a specific project in mind or would like to know more about us, we’re always ready to talk. Let’s get started with a few questions.

AU 1300 088 555 (within AU)NZ 0800 756 543 (within NZ)info@aquatecenviro.comHeadquarters

2 Provincial Crescent,

Shepparton, VIC 3630

Production Facility

56-60 Florence Street,

Shepparton, VIC 3630

Level 28, 2 Southbank Boulevard

Southbank, VIC 3006

Level 12, 50 Berry St

North Sydney, NSW 2060

9 Nello Place,

Wetherill Park, NSW

34 Kurzok Pl,

Richlands, QLD 4077

37-43 Brodie Road,

Lonsdale, SA 5160

Perth

Canning Vale, WA 6155

52 Orbell Street, Sydenham,

Christchurch 8023, New Zealand

Tenancy 5, 76 Porana Road,

Hillcrest, Auckland 0627, New Zealand