These structures were split into 4x diameter classes (2.8m, 2.4m, 1.8m and 1.2m) with depths ranging from 2.80m to 15.49m.

The structures were to comprise of an FRP vessel and concrete cover, comprising of:

The designs also needed to allow for future requirement of 3.5m additional overburden as provision for future development works. As a result, flexibility in the riser section was required to be able to achieve any height differences.

All designs needed to comply with all Sydney Water technical specifications and several standards for the structural design of the FRP and concrete elements. DSA and CivEng consulting were engaged to assist with the respective design of these components. The design of the FRP and concrete elements then needed to be submitted to independent verifiers for review and sign off before submitting to the client for final acceptance.

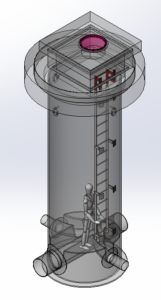

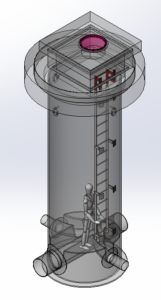

Typical DN1800 and DN1200 maintenance structure showing FRP structure, external reticulation connections, stainless-steel ladder, trunk main (internal benching) and concrete structure.

There were several challenges that the team encountered during the design process. As an FRP maintenance structure was a new product for Sydney Water, the designs were thoroughly reviewed by WRDT and Sydney Water to meet all technical requirements and ensure suitability to the application. This resulted in constant brainstorming of new ideas which often meant reworks.

Any changes that were required needed to be implemented across multiple structures – there was a stage in the project where all the structures were active and required updates to be carried out. As with all projects, time was critical, and all updates were required to be completed within tight timeframes once we had received feedback from the client.

Throughout the project, there have been over 250 drawings created, 4x structural reports developed and 2400 design hours committed to the project. Combining this with time spent by the rest of the Aquatec team through project management, scheduling, procurement, design reviews etc. along with time spent by the consulting engineers and verifiers we can see the effort and team collaboration required to bring this project to life.

Below is an image of the design generated by Aquatec as a 3D representation to show the client. These were also used to fabricate a 3D model for our tradeshows which can be seen in the Shepparton office.